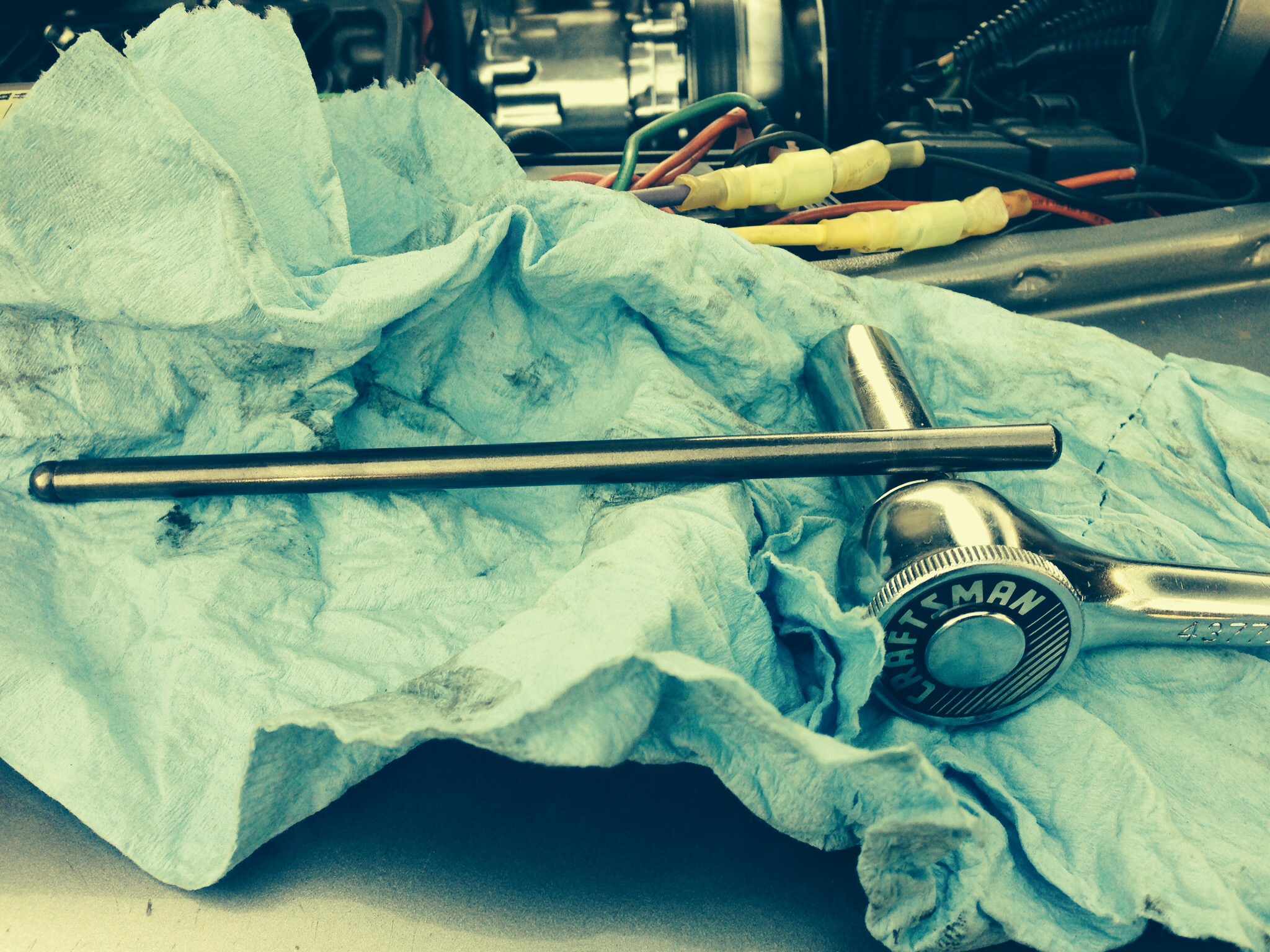

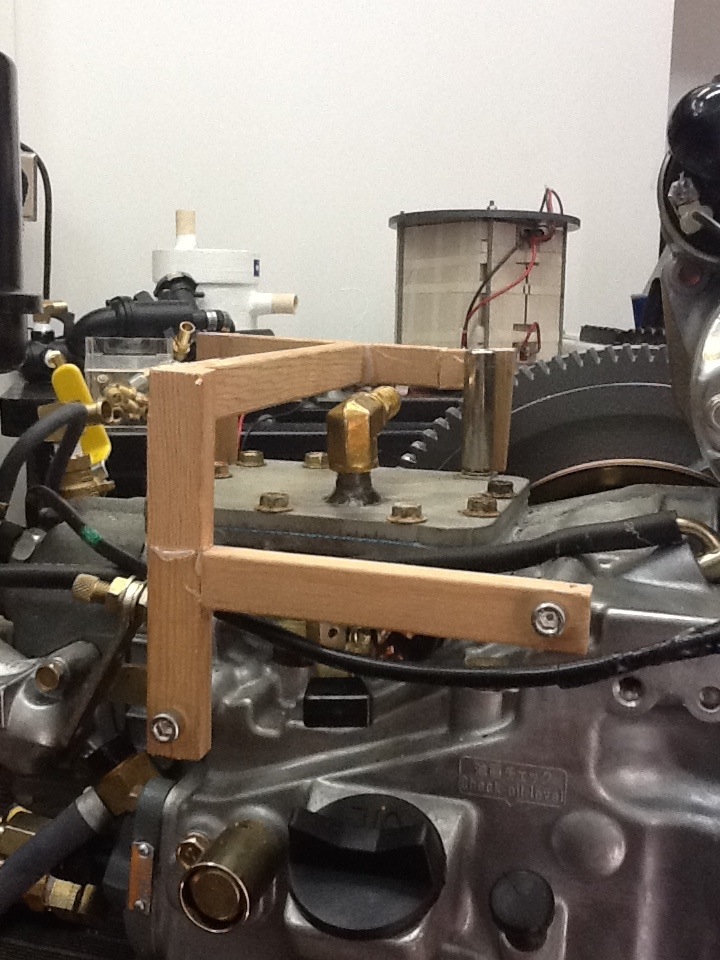

Off to the speedshop in Monroe go I. Sideways gives me a hand and we take a closer gander at my pushrod shrinkage issue. Given the rather nice valve geometry, the diagnosis of the pushrod hardness comes pretty quickly. I’m worried about the shower of metal filings that has been sent to my engine, but Sideways says I have a pretty good chance of getting away with nothing more than a filter change.

Hope in hand, I leave with a new set of stainless roller rockers, and new hardened pushrods. Sideways says I should have plenty of room in my center bolt heads. Hey maybe this won’t be so bad after all!