ZZ4 short block

My experience with engine builders and machine shops is that it is difficult to achieve a good experience without an ongoing established relationship. The reputable guys are always busy and the first red flag is a builder who is willing to immediately start work for someone they don’t know. That would be me in just about any of these scenarios.

I kicked around the idea of going for a 383, but decided against it at this stage.

The ZZ4 chevy 350 short block, direct from gm performance is the block that major engine builders such as Edelbrock use to build their own motors. They produce a known, new, not rebuilt solid foundation that out of the box reliably capable of producing up to 450 horsepower. Short of the need to build a race engine, it’s hard to beat for the cost. As a 4×4 motor, I have no intention of trying to coax 450 horse out of an engine. I don’t want to sacrifice low end torque by maxing the horsepower. I will avoid high lift cams. My goal will be to maximize the efficiency and torque of the engine. The ZZ4 4 bolt main block is about as ideal as you get and at less cost than a reputable machine shop build. As a 4×4 rig, first and foremost I want reliability, that rules out bargain basement question mark short blocks from volume builders too.

Bearing blues

The oil pan has been removed. The results are in. If I’ve learned anything about this Jeep, it’s to set my expectations that the answer to one question simply leads to more mysteries.

If I may have a quick drum roll, let me now present my first bearing!

Now, I don’t tell bearing fortunes every day, but there are some obvious issues here.

First, the fingernail test is a failure. There are two score marks that your nail gets hung up on. That by itself is a note of a bearing that needs replacing. So in fact I do have some scoring that was likely a result of the metal shower from my pushrods. Honestly, the scoring is not so bad that I think this motor would quit based on it alone.

But the scoring is not the only thing going on…

Yes, that’s a significant portion of the bearing that is showing copper bleeding through the babbet. That’s worse than the scoring and while I can’t prove it, I’d bet it has nothing to do with the metal particle scoring.

Still worse about the copper showing through the bearing material, it’s quite uneven. The crank or the bearing is not riding right. Why? Great question, but this is more than just simple wear. I don’t believe this engine has many miles on it since being built, so this is not looking good.

Another issue with the uneven wear, if you look where the bearing meets the edge of the cap, you can see what is essentially completely untouched babbet material. So, no wear by the cap edges, but worn through unevenly at the bottom of the bearing she’ll.

The net of this diagnosis based on just one bearing cap by itself tells the story. This engine needs more than just a new set of pushrods.

Blech.

A message from Comp Cams

I had left a message with comp cams about my pushrod issues. They promptly did not return my message and I summarily forgot all about them. A week later I get pinged with an apology for the late response. I share some pictures and they question my valve springs. The net of it all is that we have a pretty firm diagnosis. I have some pretty nice heads. Those heads have somewhat stiff spring pressures. I bought a kit from comp that simply won’t stand up to them and need to use hardened pushrods.

But of course! Lesson noted.

The more that time goes by, the more I don’t like the question mark of what may have gone on with oiling system and all those metal flakes. I make the decision to pull the oil pan and have a look see. Better to know than not know. I’m back to hoping for good news.

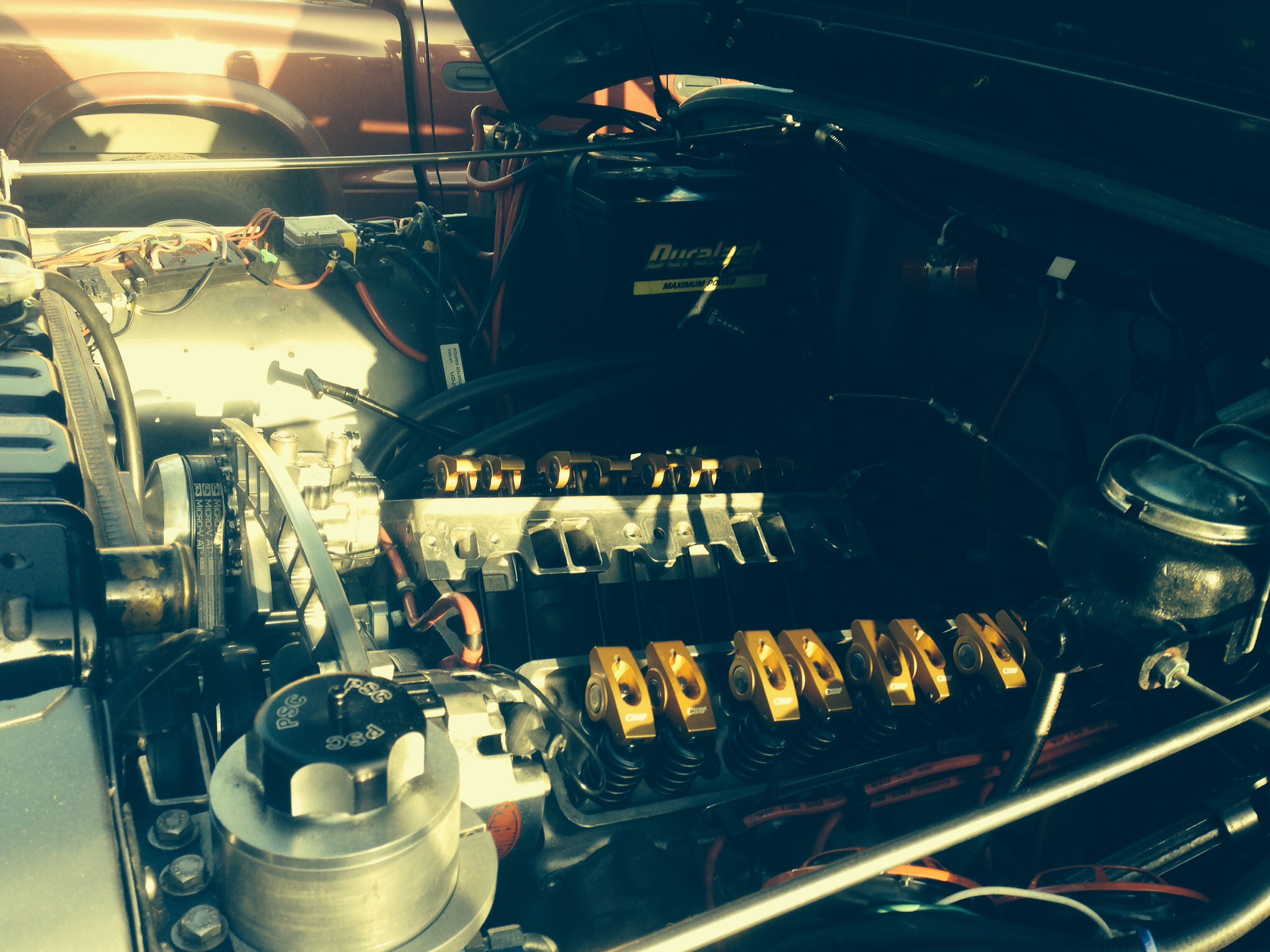

Nice shiny new gold rockers

With no small amount of déjà vu, I lay my nice new Gold rockers on my heads. Once again, I’m getting close. This will all be over soon. I can’t wait.

New shiny stainless rockers

So…I installed my nice shiny new roller rockers and pushrods. They were not cheap, but given the scenario of rebuilding the engine, it’s a small price to pay. There was only one tiny glitch in the plan. I can’t get my valve covers back on. They don’t fit.

Off to the internet I go and it does not take long to determine this is a common problem. I need narrow rockers for my centerbolt heads.

Order placed. You can get anything on Amazon. As the shampoo bottle wisdom goes…rinse, repeat.

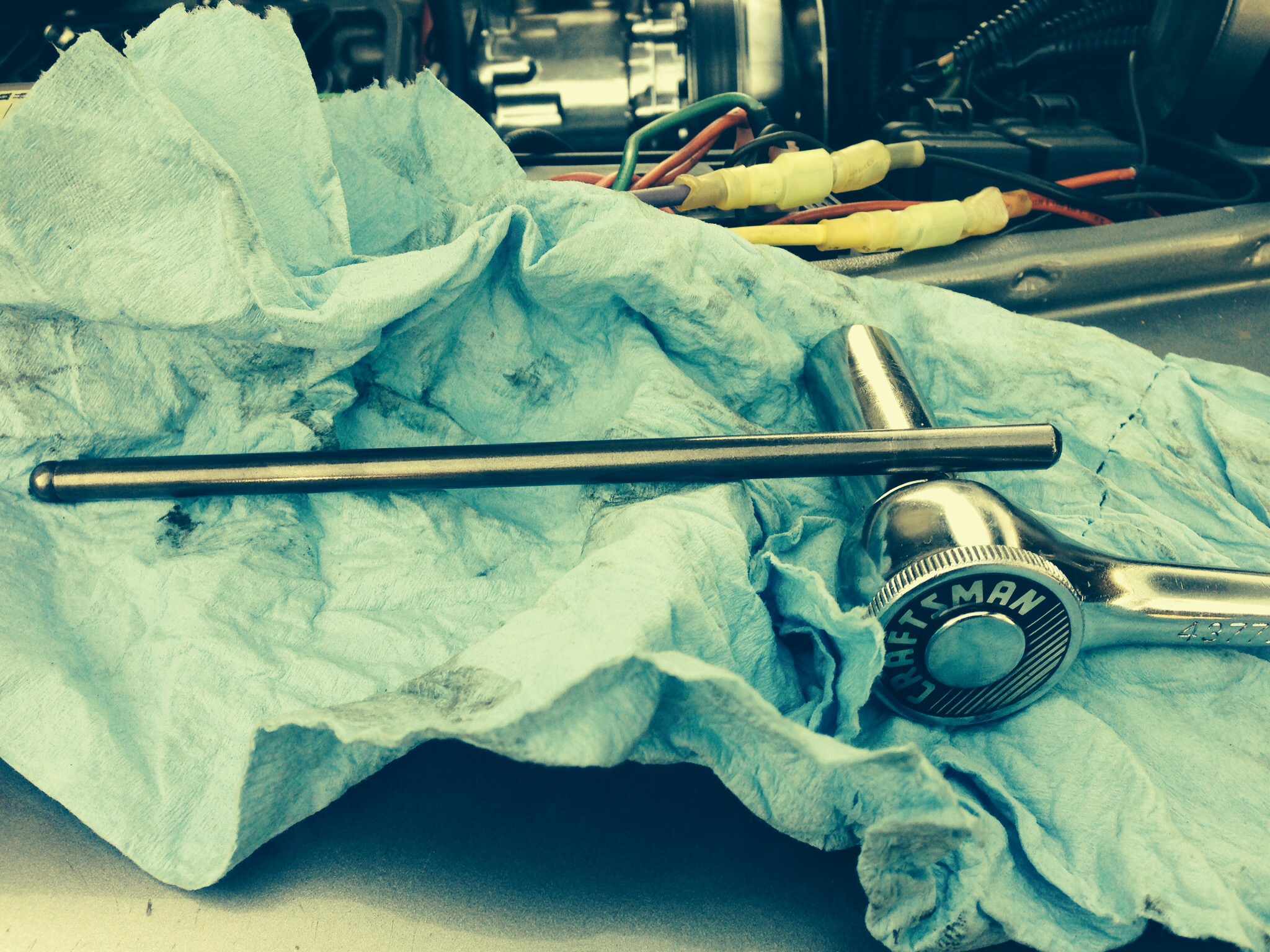

New rockers and pushrods

Off to the speedshop in Monroe go I. Sideways gives me a hand and we take a closer gander at my pushrod shrinkage issue. Given the rather nice valve geometry, the diagnosis of the pushrod hardness comes pretty quickly. I’m worried about the shower of metal filings that has been sent to my engine, but Sideways says I have a pretty good chance of getting away with nothing more than a filter change.

Hope in hand, I leave with a new set of stainless roller rockers, and new hardened pushrods. Sideways says I should have plenty of room in my center bolt heads. Hey maybe this won’t be so bad after all!

Shrinking pushrods

Traveling along the Mountain Loop highway I had noted the sound of misadjusted rocker loads. I had heard this sound before, and in fact had just done a valve adjust the morning of. I had hoped that I simply had a rocker nut that was loosening up, so got on the Internet and ordered up some polylocks. It was a bit far fetched, given they were brand new rockers pushrods and nuts, but that’s what hope and denial will do to you. Somewhere in the back of my mind I knew that was not going to do it, so when the polylocks arrived I committed to pulling a rocker or two and doing a close inspection.

The results of that inspection were pretty conclusive. My pushrods were eating themselves at the rocker arms. The worst had eaten clean through the welded ball of the pushrod end. Clearly, this is going to be a problem.

Next up was valve geometry. Which was perfectly centered across the valve stem. No problems there.

The plot thickens.

Mountain loop highway.

The Mountain loop highway between Granite Falls and Darington makes for a great Saturday day trip. It’s close, scenic and offers the right amount of rustic appeal. Plus there is little doubt that one has truly gone off the beaten path, as once the pavement ends somewhere around the ice caves you are treated to a well worn gravel road. Well worn of course as when the hillside collapsed in Oso blocking the highway into Darrington, this not so well traveled route became important to those who call the area home.

Now ow when I mean the pavement ends and one is on a gravel road, I mean a pothole filled gravel road. Potholes as I discovered that quickly laughed at even 35 inch tires. If you can’t find a clear path around the deeper ones, you had better slow down and drop each wheel in one at a time lest you find yourself turning wrenches on the side of the road.

Now, this is a route that does not require a true offroad vehicle, though it helps. You just might find yourself slowing down more frequently. But don’t let that stop you. The rustic charm is very much a part of its appeal. The highway had been closed for some time after a bridge was washed out in a winter storm, but has been back in service since 2008 after the bridge was put back in service and the roadway restored.

For me, it was a great outing and felt like it did some justice for what this Jeep was made for. Though by the time I got back onto pavement close to Darrington, I noted my engine was revealing some unwanted noise from her lifters. That will be another story, but for now try to enjoy the pictures.